Beyond Conventional Downhole Technology

Enhancing Your Directional Drilling ExperienceWe specialize in engineering and manufacturing adaptive and durable downhole technology for oil and gas well exploration, development, and production. Above all, our custom solutions focus on drastically improving your directional drilling experience. We achieve this by treating each well as it was meant to be approached: as a unique set of challenges.

Our Downhole Technologies are Your Insurance Against Costly Failures

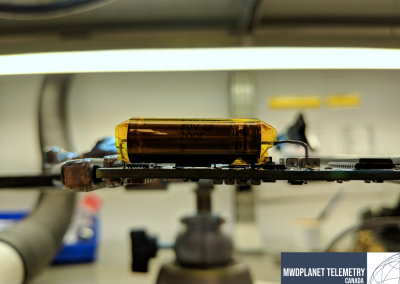

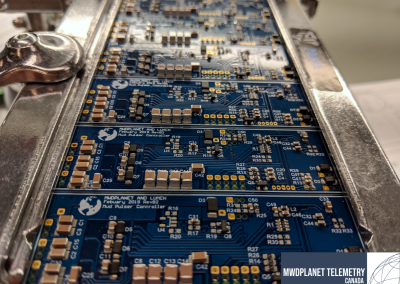

Directional Drilling Telemetry

Measuring-While-Drilling (MWD) downhole technology is used in well exploration and development. It provides essential wellbore inclination and azimuthal data for directional drilling. Thus, data accuracy and quality are critical in guaranteeing the wellbore is safely and efficiently moving in the correct direction.

We engineer a comprehensive range of Mud Pulse (MP) and Electro-Magnetic (EM) based MWD Tools. Notably, all of our telemetry tools have some of the best accuracy and longevity specifications currently available on the market.

Logging

Logging While Drilling (LWD) downhole technologies provide data about geological formations during drilling. As a result, this technology is widespread in geosteering.

Our Logging While Drilling (LWD) options are broad, to ensure subsurface measurements are detailed. For example, as a standard build, our telemetry tools:

- come with gamma logging,

- interface with resistivity tools, and

- have the expansion capability to integrate with existing neutron density tools.

Taking features even further, our near-bit tool, Voyager, provides Azimuthal Gamma readings.

Near-Bit Measurements

Near-bit technology positions sensors directly behind the drill bit, effectively eliminating lag time between the sensor and the bit. The readings you receive are as real-time as possible for the position of the bit. As a result, near-bit measurements are indispensable for geosteering in tight formations, long laterals, and horizontal directional drilling.

Our near-bit tool, Voyager, provides critical data near the drill bit such as:

- Inc at Bit,

- Gamma at Bit,

- and Azimuthal Gamma for geosteering applications.

Near-bit technology is also essential in collision avoidance applications, where tight steering and quick decision-making are critical.

River-Crossing Directional Drilling

River-crossing directional drilling, also known as horizontal directional drilling, is fast, shallow and sports huge flow rates. To add to the stakes, permitted margin of error is almost non-existent.

To meet these demands, we build our multi-channel Electro-Magnetic (EM) tools with accuracy, versatility, and ease of service in mind. For even more added accuracy of bit position data, our near-bit tool, Voyager, helps with accurate inclination measurements directly at the drill bit, guaranteeing the information you are receiving is truly real-time.

Production

Producing well monitoring technologies ensure the longevity and safety of your existing wells. Our pressure monitoring production tool, Tysk, empowers your workflow with the data about your speed of extraction, flow control, and pump health.

Thermal Well Drilling

As a fully custom and proprietary solution, we design and manufacture tools for extreme directional drilling conditions in the 200°C-220°C range. We can help make your next high-temperature/high-pressure (HTHP) drilling expedition a success.

General templates that worked yesterday are now expensive mistakes

in a quickly-changing landscape of oil and gas drilling.

What is Your Total Loss for Each Hour of Standby?

Innovation as an Asset

We do not stop looking forward. Thus we develop each specification in our downhole technologies with the following questions in mind:

“How does this integrate into the problem-solving needed in directional drilling years from now?”, and

“How does this help our clients generate long-term profit?”

For these reasons, we develop solutions specifically to your individual drilling needs, whether upstream or downstream. As a result, our tools incorporate seamlessly into your existing fleet and help ease transitions through the various production stages of your well.

The industry demands the best;

We help you achieve that.

Our Solutions Are

Durable

Adaptive

Highly-Specialized

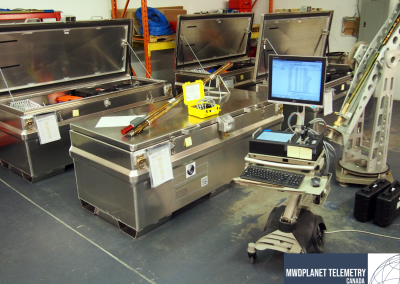

Build Your Fleet

Whether you know exactly what challenges are ahead or are at a loss of what to expect, we will help you identify your technological needs. Our company will provide you with custom downhole solutions that will become your biggest assets at the drill site, while seamlessly integrating into existing workflows.